We can learn the ways of the old ones by going back to how they ate before the Industrial Revolution, back when there was integrity, family and story involved in producing an artisan product by hand. With the help of Slow Food and other movements, there is a global resurgence to grow locally and create the artisan story as well. It’s nothing new and yet, it is. We have not been taught to eat what grows around us in season and preserve for the cooler months. Or if we have, we choose not too. We don’t have time perhaps, but worse still, is that we have little relationship to what grows in season or the absolute heightened taste that comes with it. We are used to picking anything up at the grocery store that we need. Acidic pineapple. Tomatoes that taste like mush. Puckering mangos. We (most Americans) feel entitled to have what we want at all times, without thinking of the implications. We may be spoiled, but if you think about, we are not. We are just missing out.

There is an Italian cook book from 1891 called, “La Scienza in cucina e l’Arte di mangiar bene”. Science in the kitchen and the Art of eating well by Pelligrino Artusi. Artusi was a Florentine silk merchant, a gastronome, a bon vivant, a noted raconteur, and a celebrated host, who knew many of the leading figures of his day and read widely in the arts and sciences. What this book offers is a way of life. That food, how we prepare it and how we feed ourselves, should not be separate from how we live. If we care about cultivating our minds in an intelligent, mindful and artful way, why not how we eat?

After all, the best conversations are born at the table, whether you are happy or sad, having a good cup of tea, a simple meal or a banquet. Whether you are with one or several, or even alone, you can appreciate the finer nuances of life in the simplest hearty bowl of soup or polenta with olive oil and grated parmigiano. You can appreciate the color of the corn, contemplate how it was ground, who grew it and in what region. A drizzle of spicy, peppery olive oil reminds us of the care the “contidini”who looked after the trees, harvested the olives in cold November and waited hours at the frantoio. Sometimes they wait through the night. The machines never stop during harvest. They must watch to make sure their olives don’t end up as someone else’s oil. They hold court for their freshly picked fruit to pass through the press and flow out bright green, pungent and full of antioxidants. Extra virgin olive oil. Our hero. A compliment to any dish. Even ice cream.

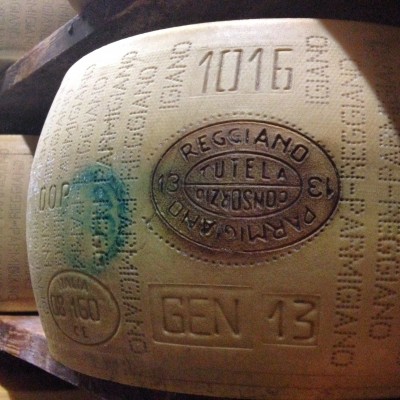

You might wonder about the complexity of parmigiano reggiano and why they call it the king of cheeses, probably not knowing that a wheel is actually ‘born’ and that the process of aging is controlled by an expert grader from the Consortium that tests each wheel with a small hammer to make sure it’s worthy of the stamp of approval. Read here for the full disclosure of how the King is born. http://www.parmigianoreggiano.com/made/parmigiano_reggiano_cheese/default.aspx.

I have experienced it myself in Pavullo, on cold dark mornings at 6 am. First comes the milk from the black and white cows, which we have said good morning to, then the process begins in deep copper vats. It’s quite a process of steps and by 8 am, the curds have separated from the whey and collected at the bottom of the vat. The cheese maker midwife, takes a long wooden paddle and slides it underneath the form at the bottom and with a lot of strength, uplifts and “births” about a 200 pound cheese that gets separated into two rounds (as it they were twins) and are hung in muslin and strapped to a poll to drip until it’s pressed ” into a stainless steel, round form that is pulled tight with a spring-powered buckle so the cheese retains its wheel shape. After a day or two, the buckle is released and a plastic belt imprinted numerous times with the Parmigiano-Reggiano name, the plant’s number, and month and year of production is put around the cheese and the metal form is buckled tight again. The imprints take hold on the rind of the cheese in about a day and the wheel is then put into a brine bath to absorb salt for 20–25 days. After brining, the wheels are then transferred to the aging rooms in the plant for 12 months. Each cheese is placed on wooden shelves that can be 24 cheeses high by 90 cheeses long or about 4,000 total wheels per aisle. Each cheese and the shelf underneath it is then cleaned manually or robotically every seven days. The cheese is also turned at this time.

At 12 months, the Consorzio Parmigiano-Reggiano inspects every wheel. The cheese is tested by a master grader who taps each wheel to identify undesirable cracks and voids within the wheel. Wheels that pass the test are then heat branded on the rind with the Consorzio’s logo. Those that do not pass the test used to have their rinds marked with lines or crosses all the way around to inform consumers that they are not getting top-quality Parmigiano-Reggiano; more recent practices simply have these lesser rinds stripped of all markings.” This is just the making of the king of the cheeses that is grated on your favorite dish, not to mention the life of the farmer and his wife and children who can never leave the farm or miss a morning.